Oil distribution equipment

Oil dispensers of the “Shelf” MRK series are designed for dispensing motor lubricants and meet the latest requirements for modern gas stations.

Specifications ``Shelf`` MRK-1

| Flow rates, l/min | 12 |

| Deviation from the norm | ±1% |

| The minimum dose of oil delivery, l | 2 |

| Nozzle amount | 1 |

| Number of oil | 1 |

| Electronic calibration | yes |

| Number of pump | 1 |

| Product types | motor oil |

| Temperature range | -40/+50°С |

| Power supply | 230/400V +/- 10%, 50 Hz+/- 2Hz |

| Access control | ЕК Dallas |

| Hose length, m | 4 |

| Display | LCD or LED |

| Capacity of the counting device | 9999,99 l |

| Total counter | electronic 12-bit |

| Dimensions H/W/D, mm | 1620 /600/370 |

| with packaging H/W/D, mm | 1720 /600/650 |

| Weight, kg | 145 |

DEVICE CONFIGURATION

Standard equipment:

- Oil pump

- Flowmeter

- Oil nozzle

- High pressure hose

- Backlit LCD

- Memory touch (Dallas)

Possible additional equipment:

- LED

Technical documentation

Specifications ``Shelf`` MRK-2

| Flow rates, l/min | 12 |

| Deviation from the norm | ±1% |

| The minimum dose of oil delivery, l | 2 |

| Nozzle amount | 2 |

| Number of oil | 2 |

| Electronic calibration | yes |

| Number of pump | 2 |

| Product types | motor oil |

| Temperature range | -40/+50°С |

| Power supply | 230/400V +/- 10%, 50 Hz+/- 2Hz |

| Access control | ЕК Dallas |

| Hose length, m | 4 |

| Display | LCD or LED |

| Capacity of the counting device | 9999,99 l |

| Total counter | electronic 12-bit |

| Dimensions H/W/D, mm | 1620 /600/370 |

| with packaging H/W/D, mm | 1720 /600/650 |

| Weight, kg | 145 |

DEVICE CONFIGURATION

Standard equipment:

- Oil pump

- Flowmeter

- Oil nozzle

- High pressure hose

- Backlit LCD

- Memory touch (Dallas)

Possible additional equipment:

- LED

Technical documentation

Specifications ``Shelf`` MRK-3

| Flow rates, l/min | 12 |

| Deviation from the norm | ±1% |

| The minimum dose of oil delivery, l | 2 |

| Nozzle amount | 3 |

| Number of oil | 3 |

| Electronic calibration | yes |

| Number of pump | 3 |

| Product types | motor oil |

| Temperature range | -40/+50°С |

| Power supply | 230/400V +/- 10%, 50 Hz+/- 2Hz |

| Access control | ЕК Dallas |

| Hose length, m | 4 |

| Display | LCD or LED |

| Capacity of the counting device | 9999,99 l |

| Total counter | electronic 12-bit |

| Dimensions H/W/D, mm | 1620 /600/370 |

| with packaging H/W/D, mm | 1720 /600/650 |

| Weight, kg | 145 |

DEVICE CONFIGURATION

Standard equipment:

- Oil pump

- Flowmeter

- Oil nozzle

- High pressure hose

- Backlit LCD

- Memory touch (Dallas)

Possible additional equipment:

- LED

Technical documentation

Specifications ``Shelf`` MRK-4

| Flow rates, l/min | 12 |

| Deviation from the norm | ±1% |

| The minimum dose of oil delivery, l | 2 |

| Nozzle amount | 4 |

| Number of oil | 4 |

| Electronic calibration | yes |

| Number of pump | 4 |

| Product types | motor oil |

| Temperature range | -40/+50°С |

| Power supply | 230/400V +/- 10%, 50 Hz+/- 2Hz |

| Access control | ЕК Dallas |

| Hose length, m | 4 |

| Display | LCD or LED |

| Capacity of the counting device | 9999,99 l |

| Total counter | electronic 12-bit |

| Dimensions H/W/D, mm | 1620 /600/370 |

| with packaging H/W/D, mm | 1720 /600/650 |

| Weight, kg | 145 |

DEVICE CONFIGURATION

Standard equipment:

- Oil pump

- Flowmeter

- Oil nozzle

- High pressure hose

- Backlit LCD

- Memory touch (Dallas)

Possible additional equipment:

- LED

Technical documentation

Oil Pump

Before installing an oil pump, pay attention to the condition of the hydraulic system and all its components, as the premature failure of the pump can be due to violation of operating rules and because of state of the whole hydraulic system. When installing the pump, the following conditions must be observed: When a pump is running, STOP REPAIR WORKS AND DO NOT REMOVE STEEL BOLTS.

Remove all defects appeared during the operation. It is necessary to remove defects only after full stop of the pump. When operating the pump it is necessary to сheck the level of oil in the tank, its quality, as well as the tightness of all connections of pipelines especially suction, because the suction of air leads to foaming and is absolutely unacceptable. Before operating the pump at negative ambient temperatures, the working fluid must be warmed up. For this purpose, the pump must operate without loading until the temperature of the working fluid in the hydraulic system is reached 10 ° C, after which it is possible to operate under loading

It is necessary to check the mounting flange of the pump drive for damages; check absence of distortion and increased wear of the coupling of the pump drive. If damages are detected, they should be removed, otherwise axial and radial loadings are transmitted to the shaft of the pump , then the vibration of the pump appears and increases the bearings degradation.

It is not possible to change the direction of entry and exit of the oil pump, as this may result to the displacement of the working fluid of the gland ejection drive gear.Check the conformity of the direction of rotation pump drive and the shaft of the pump, with divergence of directions of rotation, the extrusion of pump shaft ring starts. Pump processing in order to change the direction of rotation is not recommended, as this leads to loss of operation characteristics , significantly reduction of service life of the pump, and loss of the guarantee.

The suction pipes and the tank of the hydraulic system must be cleaned of dirt and thoroughly washed. Before starting the system after its maintenance, it is necessary to install a new filtering element or a carefully washed old one, also it is necessary to clean the valve. Check the quality and properties of the working fluid. It is forbidden to operate the pump if there is the presence of water in oil and mechanical impurities above the norm. To determine their presence you can visually, the olive spots on paper are grey or black. In the case of oil pollution, the oil should be replaced or cleaned, otherwise the destruction of the pump parts starts because of hydroabrasive wear.

If necessary, replace the oil, it is necessary to wash the hydraulic system too. The oil mark must correspond to the machine’s operating instructions

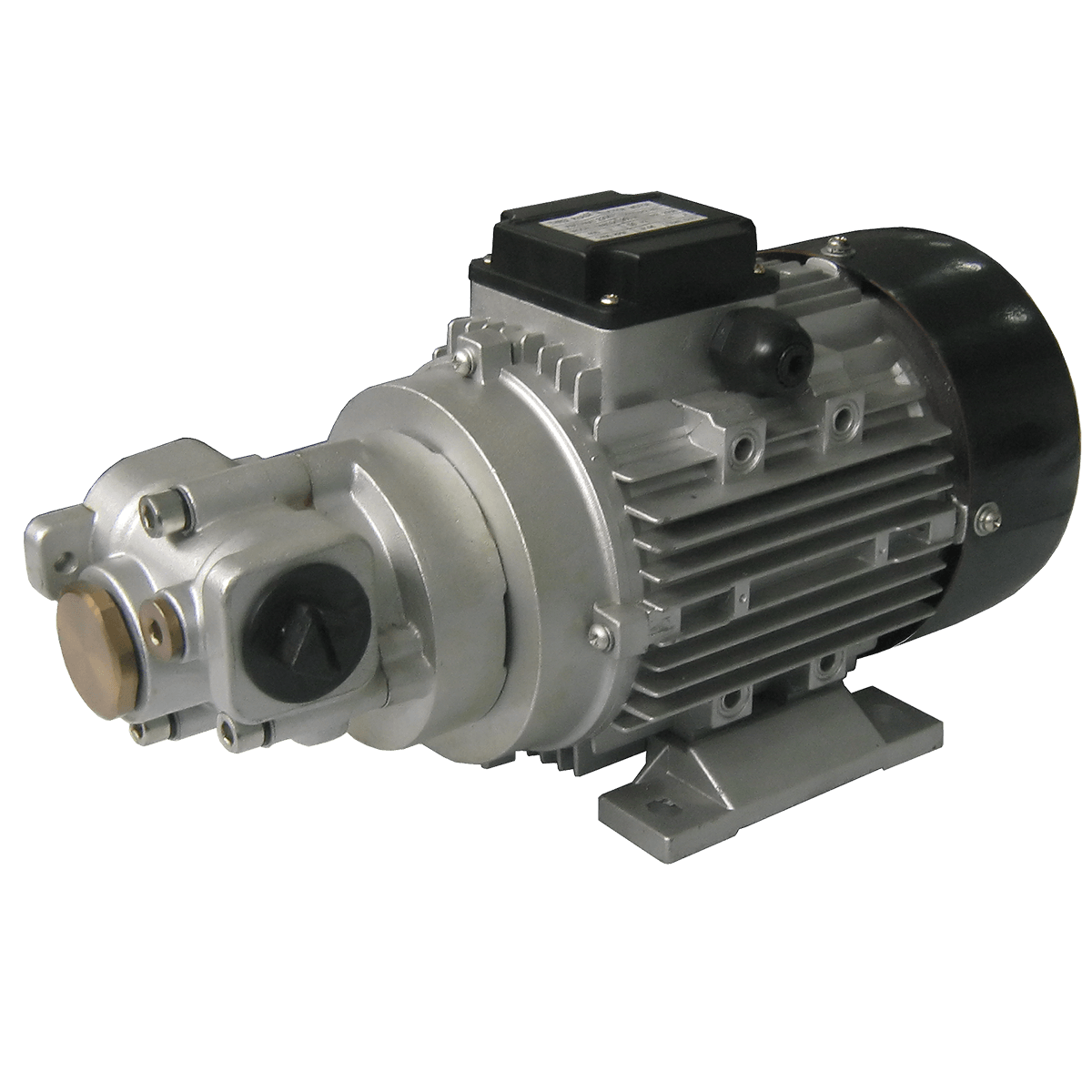

Oil Pump 1

| Motor oil pump 1 | Об'ем,V,м3 |

| Productivity, l/min.: | 18.3 |

| Power supply, V: | 380 |

| Power consumption, W: | 1500 |

| Speed, rpm: | 1400 |

| Pump type: | gears |

| Noise level, dB: | 70 |

| Protection class, IP: | 55 |

| Uninterrupted operation time, min.: | no time limit |

| Pressure, Bar: | 14,5 |

| Input-output, in (mm): | 3/4" (20) |

| Suction height, m: | shall not exceed 1 m |

| Working temperature ̊C: | from +10 to +180 |

| Viscosity, сSt | no more than 350 cSt |

| Weight, kg: | 15 |

| Dimensions (LxWxH), mm: | 583 х 265х 280 |

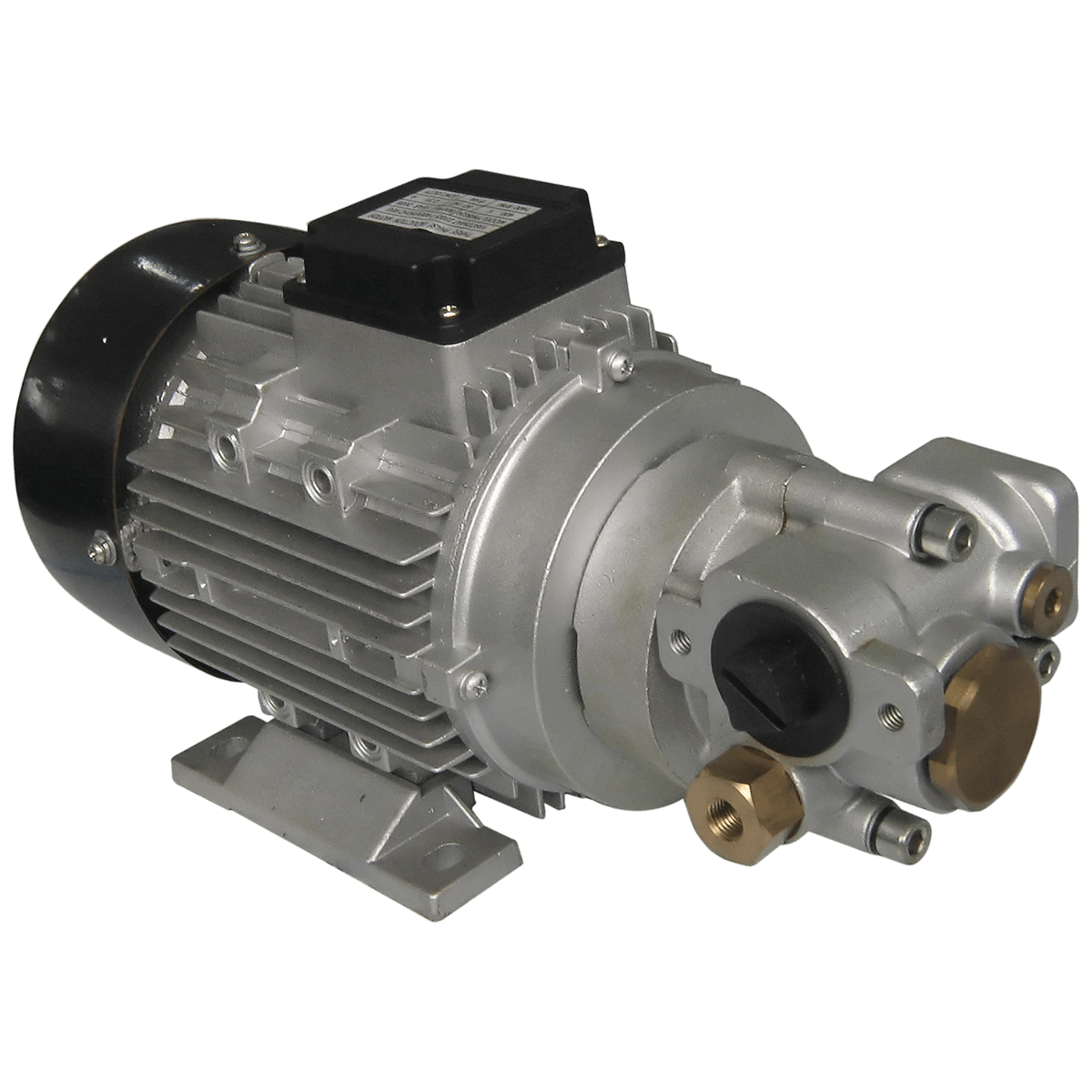

Oil Pump 2

| Motor oil pump 2 | Об'ем,V,м3 |

| Productivity, l/min.: | 9 |

| Power supply, V: | 220 |

| Power consumption, W: | 900 |

| Speed, rpm: | 1550 |

| Pump type: | gears |

| Noise level, dB: | 70 |

| Protection class, IP: | 55 |

| Uninterrupted operation time, min.: | no time limit |

| Pressure, Bar: | 12 |

| Input-output, in (mm): | 1" (25) |

| Suction height, m: | shall not exceed 1 m |

| Working temperature ̊C: | from +10 to +180 |

| Viscosity, сSt | no more than 350 cSt |

| Weight, kg: | 9 |

| Dimensions (LxWxH), mm: | 350 х 200 х 280 |

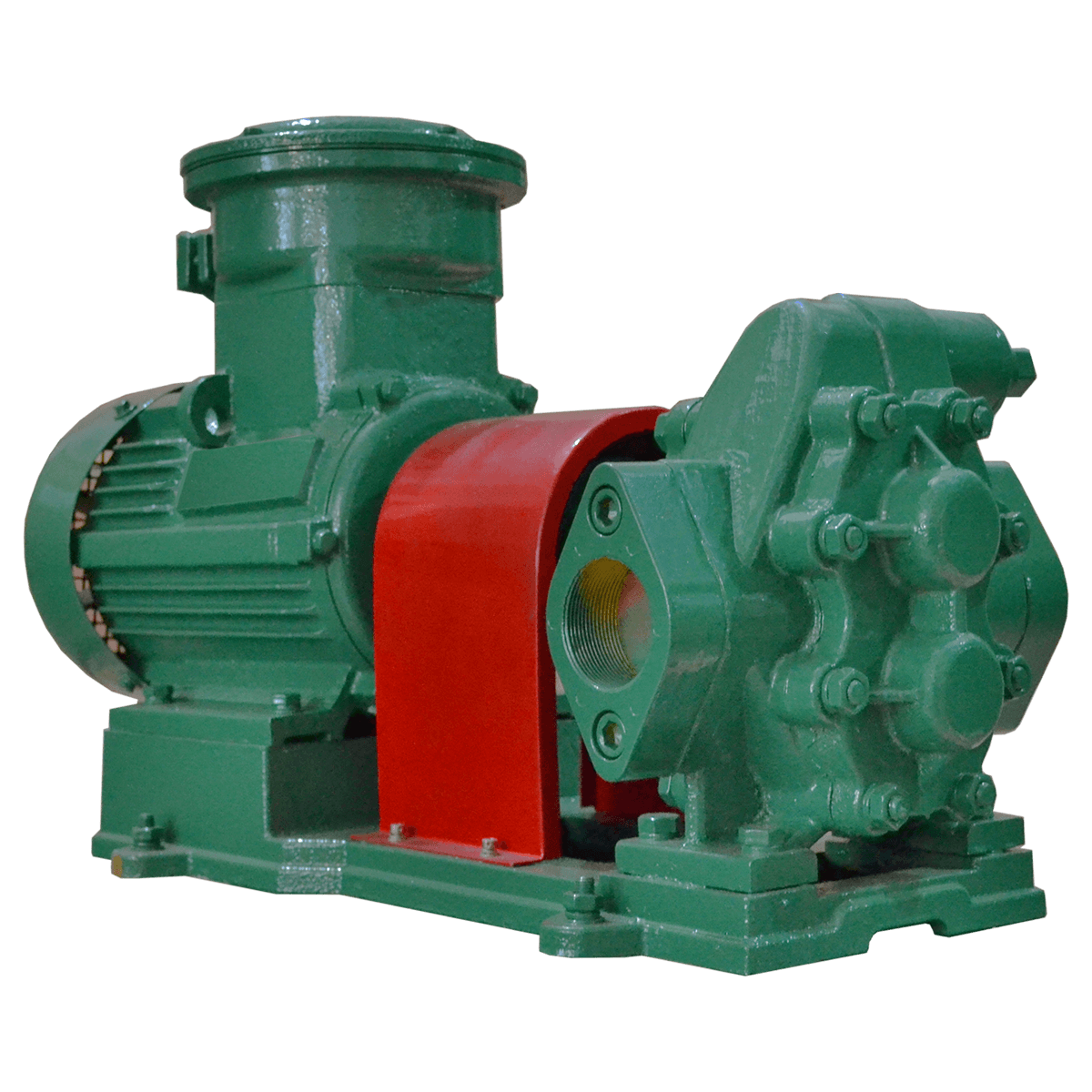

Oil Pump 3

| Motor oil pump 3 | Об'ем,V,м3 |

| Productivity, l/min.: | 200 |

| Power supply, V: | 380 |

| Power consumption, W: | 4000 |

| Speed, rpm: | 1440 |

| Pump type: | gears |

| Noise level, dB: | 70 |

| Protection class, IP: | 55 |

| Uninterrupted operation time, min.: | no time limit |

| Pressure, Bar: | 3.3 |

| Input-output, in (mm): | 2" (50) |

| Suction height, m: | shall not exceed 1 m |

| Working temperature ̊C: | from +10 to +180 |

| Viscosity, сSt | no more than 350 cSt |

| Weight, kg: | 120 |

| Dimensions (LxWxH), mm: | 709 х 326х 356 |